EQUIPMENT

Henkel’s Equipment Engineering Group is a group of specialized equipment that designs, assembles and tests customized equipment systems and processes for application and curing of adhesives in the field.

Henkel’s Equipment Engineers work with customers from the initial development stage of the product, providing a complete solution from the choice of adhesive to the production line of the machine.

PRODUCT

Dispensing Equipment

- Silicone Dispensing Equipment

It is a device that applies silicone to places where various sealing such as automobile engine and transmission are required. Air pump of different capacity is used according to the viscosity of silicon.

In addition to air pumps, dispensing equipment includes metering pump, regulator high-low pressure hose and heating device for lowering the temperature in winter.

- Rotor pump

It is a pump that discharges all adhesive liquid except instant adhesive, and it can be dispensed by rotary displacement discharge method.

The amount discharged from the pump is proportional to the rotational speed and the drive shaft is sealed with a double ring made of UHMW-PE and PTFE.

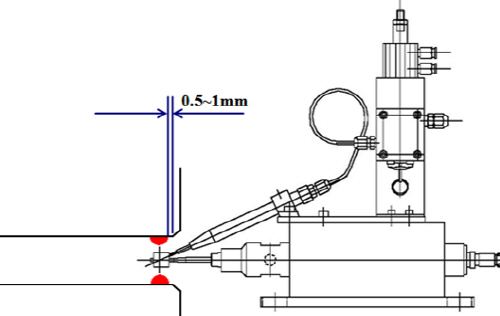

- Anaerobic Dispensing Equipment

It is applied to various applications of automobile engine and transmission through various equipment considering characteristics of anaerobic liquid.

- Bag Dipenser

As an equipment for application of anaerobic products, 2L exclusive plastic packs have the following advantages over the use of conventional plastic containers.

– Minimize remaining amount after use (Maximize usage)

– Comfortable work environment (prevention of liquid splashing)

– Extension of storage period

– Fluid exchange test notice (24V Output, Lamp)

- Rotospary

It is a device that injects a certain amount of fluid by using centrifugal force and has the following advantages.

– Control of application amount using quantitative valve

– Prevent overspray by controlling spray amount

– Minimize work time by using high-speed motor

– Applicable to various sizes of holes

Dispensing Examination Equipment

It is a system to prevent defects by comparing and analyzing defects that occur during the process of automatic application of liquid such as silicon or anaerobic to the data of normal application process prepared in advance.

- Flow monitor system2

It is a system that reads the pressure change when applying adhesive with high accuracy sensor, and it can check continuity and break of bead during anaerobic and silicone application through pressure graph displayed on the screen.

- FEATURE

- Economical application device

- Simple operation method

- Easy to identify abnormality through graph * Defective valve operation

- Network communication possible

- INSPECTION LIST

- Nozzle clogging

- Bubble generation

- Defective valve operation

- Poor supply of liquid

- Hose breakage

- Rotor pump

It is a pump that discharges all adhesive liquid except instant adhesive, and it can be dispensed by rotary displacement discharge method. The amount discharged from the pump is proportional to the rotational speed and the drive shaft is sealed with a double ring made of UHMW-PE and PTFE.

- Camera System

By sharing real-time information between robot and camera system, it is possible to check the application status simultaneously with application of adhesive. Two CCD cameras are installed next to the nozzles, so you can check the abnormalities of the images compared to the initial normal data by taking more than about 200 pictures per second.

Automatic reapplication is possible in the non-application section.

- Fluorescence Detector

Fluorescent detectors allow you to check whether the adhesive is coated or not, and you can monitor the dispensing cycle in real time.

Henkel’s fluoroscopy equipment is highly accurate and reliable.

(However, the fluorescent substance must be contained in the adhesive.)

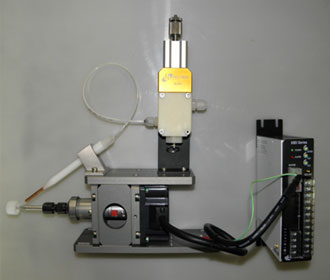

IE Rotor Spray

It is equipment set which applies anaerobic adhesive to material hole by using torque.

The components consist of an IE47 tank for storing the adhesive, an IE2004 metering valve for supplying the adhesive, and an IE2223 electric motor for applying the supplied adhesive to the hole.

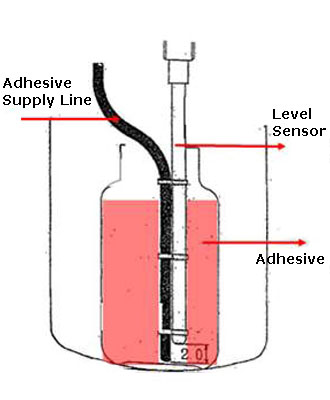

IE47 Adhesive Tank

Size: Φ215(D)x360mm(H)

** Maximum Pressure Applicable Range: 6.0kg / Cm2 (Max)

** Material: Stainless steel, t = 2mm

** Capacity: 10Liter

** Internal container: HDPE 5Liter container

** Liquid level sensor (LIC-75)

IE2233 Electric Motor

(1) Appearance size

** Electric motor type: 333mm (L) x 319mm (H) x 80mm (w)

** Weight: about 4kg

(2) Electric motor specification

** Motor type: BLDC (Brush Less DC motor)

** Appearance size: 80 × 42.5mm

** Maximum number of revolutions: 3,000rpm / min

** Speed control range: 300 – 3,000RPM

** Axis diameter: Φ8

IE2004 Constant Flow Valve

Constant Flow Rate Valve (IE2004)

** Constant flow rate (volumetric) application valve

** Appearance size: 197mm (L) x 50mm (H) x36mm (w)

** Liquid inlet diameter: Φ6

** Discharge diameter: Φ3

** Liquid discharge pressure: 3Kg / Cm2 (Max)

** Operating pressure: 2Kg / Cm2 or more

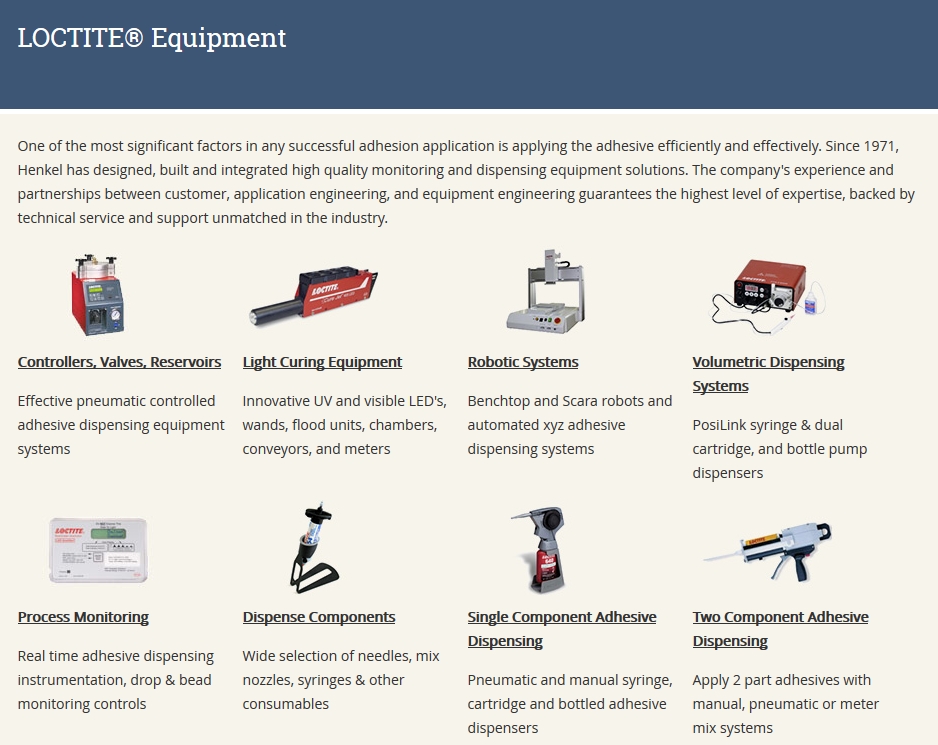

We are a distributor of Henkel Loctite’s auto equipment.

Inochem has been applying and introducing state of the art technologies and new products such as industrial tape and sealant for general industrial products of Korea and it plays role for the foundation of industrial development as a professional company.

Inochem has been applying and introducing state of the art technologies and new products such as industrial tape and sealant for general industrial products of Korea and it plays role for the foundation of industrial development as a professional company.