THREAD LOCK COATING

We will always strive to become a company trusted by our customers with the best service and management.

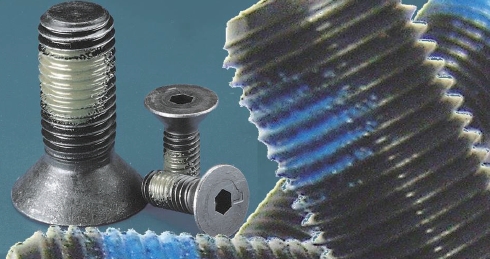

WHAT IS THREAD LOCK COATING ?

It renders functions such as locking (loosening prevention effect), sealing (leakage prevention effect)

and adjusting (adjustment effect)to coated screw by coating special sealant or make fusion processing

in the thread of screw (bolt, nut, screw).

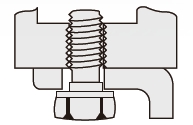

Principle of thread lock coating

-

Micro capsule type

After apply micro capsulized epoxy resin or acrylic resin as main ingredient to the screw, the micro capsule is destroyed when bolt and nut are locked and hardening reaction is made by mix of main material and hardener and finally, sticking force is made as the gap is filled. -

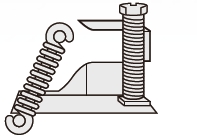

Fusion type

Once resin is applied to screw thread by fusion coating, strong friction keeping force is made in- between locked parts by strong toughness and elasticity of the resin when bolt and nut are locked so sticking force is finally made.

- Demonstrates functions of sealing and adjusting at the same time when the screw is locked.

- Automation in production line is possible as it is pre-coated type so productivity is improved.

- It has much better durability than other fixing device as its environmental resistance and chemical resistance are excellent.

- Its service life is long and re-use is possible.

- Bonding strength can be controlled by adjusting the amount of applied coating sealant.

- Various screws (M1.0-M40)can be coated.

| TYPE | 2353 | 2510 |

| COLOR | Blue | Ivory or orange |

| INGREDIENT | Epoxy | |

| USAGE | Locking & Sealing | |

| HEAT RESISTANCE TEMPERATURE | -54 ~ +116 ℃ | -54 ~ +150 ℃ |

| CLASSIFICATION | Normal | High temperature |

| HARDENING | 72 hr | 72 hr |

3M Scotch grip

Features of 3M Scotch Grip

Its main ingredient is epoxy resin contained in micro capsule (20-70u) so locking and sealing capability is excellent. Also, it can be used even in high temperature and high pressure condition of engine system as well as it can be used for automobile, general parts, cellular phone and small sized electric appliances as its anti vibration, shock resistance, gas resistance and heat resistance is excellent.

Advantages of 3M screw processing

- Advantages of 3M screw processing It makes locking and sealing effect at the same time when bolt is locked as it is per-applied type.

- Its service life is long and can be reused.

- Its sealing performance is so excellent as it can withstand 420kg/㎠ of water pressure and gas pressure.

- It can be applied to small sized screw as micro capsule is 20~70 ㎛.

- It can be applied to various screws from M1 to M50.

- Cost saving is possible as no washers, pins and double nuts are required.

- Bonding strength can be controlled by adjusting the amount of applied coating sealant.

- Automation in production line is possible as it is pre-coated type so productivity is improved.

- It complies with international standards IF1-125 and IFI-525.

ND Microspheres

Features of ND Microspheres

It demonstrates locking & sealing effect immediately when locked to screw part of bolt, nut and pipe using capsulized epoxy sealant as main ingredient. It is credible coating brand approved by domestic and foreign big automobile makers including Hyundai/KIA, GM and Chrysler.

Merits of ND Microspheres screw processing

- It makes locking and sealing effect at the same time when bolt is locked as it is pre-applied type.

- Its service life is long and can be reused.

- Its sealing performance is so excellent as it can withstand 420kg/㎠ of water pressure and gas pressure

- It can be applied to small sized screw as micro capsule is 20~70 ㎛.

- It can be applied to various screws from M1 to M50.

- Cost saving is possible as no washers, pins and double nuts are required.

- Bonding strength can be controlled by adjusting the amount of applied coating sealant.

- Automation in production line is possible as it is pre-coated type so productivity is improved.

- It complies with international standards IF1-125 and IFI-525.

- Merits of ND Microspheres screw processing

| TYPE | 593S | 1193S |

| COLOR | Blue | Ivory or orange |

| INGREDIENT | Epoxy | |

| USAGE | Locking & Sealing | |

| COVERAGE | M4 ~ M40 | |

| HEAT RESISTANCE TEMPERATURE | -54 ~ +148 ℃ | -54 ~ +148 ℃ |

| HARDENING | 72 hr | 72 hr |

| PRODUCT | DRI-LOC | VIBRA-SEAL | ||||

| D type | F type | 503 | 516 | |||

| 200 | 201 | 204 | 2040 | |||

| COLOR | Yellow | Yellow | Red | Red | White | Brown |

| COVERAGE | M1.2~60 | M6~50 | M1.2~60 | M1.2~60 | M3~60 | M3~60 |

| OPERATING TEMPERATURE | -54~+150 | -54~+204 | -54~+150 | -54~+150 | -54~+150 | -54~+150 |

| INITIAL HARDENING | 30min | 30min | 30min | 30min | – | – |

| HARDENING | 72hr | 72hr | 72hr | 72hr | – | – |

Loctite VIBRA-SEAL, DRI-SEAL

Features of Loctite VIBRA-SEAL, DRI-SEAL

It is pre-coating type sealant of which main ingredient is water soluble acrylic that is not harmful to human body and it has selfsealing effect not reactivity. Especially, its high temperature-heat resistance as well as solvent resistance is outstanding.

Advantages of Loctite VIBRA-SEAL, DRI-SEAL

- Locking torque is stabilized.

- It can be reused depending on the environment for use.

- Range of applicable temperature is wide as its temperature resistance is very strong.

- It is eco-friendly as water soluble resin is applied and can be cleaned easily.

- It is not harmful even if it is used directly to various leakage parts and also, it is safe as it is not burned by fire.

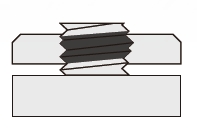

Nylon Coating

Features of Nylon Coating

Nylon is main ingredient. It performs loosening prevention effect by keeping strong friction force in the screw which is locked by toughness and elasticity of nylon itself after resin is fusion processed in screw thread or nut thread. Re-usability is excellent thanks to special characters of nylon resin and it can be used in oily condition.

Function of Nylon Coating

Loosening is prevented against external vibration and continuous shock by applying partial coating to bolt and nut.

It is a system that can control locking and loosening of the product while sticking force is being kept and the system can control the product easily.

It performs sealing in liquid, gas or similar system by applying coating to entire part of bolt and nut.

| Thread designation | fastening TORQUE(max) | 1 annealing TORQUE (min) |

5 annealing TORQUE (min) |

|---|---|---|---|

| M 1.6 x 0.35 | 1.01 | 0.099 | 0.04 |

| M 2.0 x 0.40 | 1.98 | 0.20 | 0.10 |

| M 2.5 x 0.45 | 3.98 | 0.50 | 0.30 |

| M 3.0 x 0.50 | 5396 | 1.40 | 0.60 |

| M 4.0 x 0.70 | 11.82 | 2.58 | 1.60 |

| M 5.0 x 0.80 | 22.58 | 3.60 | 2.26 |

| M 6.0 x 1.00 | 42.45 | 4.45 | 3.00 |

| M 8.0 x 1.25 | 98.20 | 8.85 | 5.69 |

| M 10.0 x 1.50 | 137.3 | 17.86 | 10.82 |

| M 12.0 x 1.75 | 206.4 | 25.50 |

Inochem has been applying and introducing state of the art technologies and new products such as industrial tape and sealant for general industrial products of Korea and it plays role for the foundation of industrial development as a professional company.

Inochem has been applying and introducing state of the art technologies and new products such as industrial tape and sealant for general industrial products of Korea and it plays role for the foundation of industrial development as a professional company.